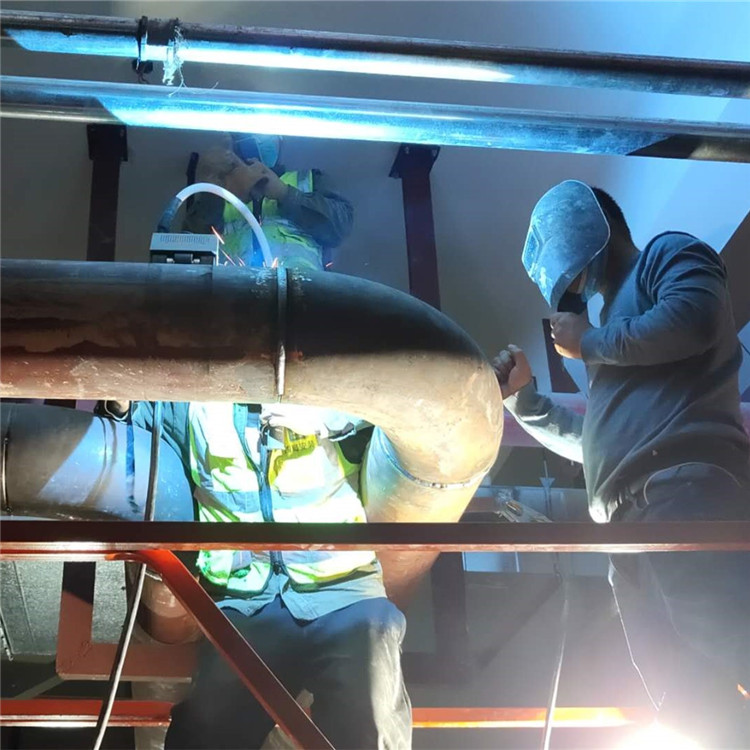

Pipeline Automatic Welding Machine

This series of automatic pipe welding machines are mainly used for automatic welding of various on-site and prefabricated pipes. The applicable pipe diameter is above 114mm, and the wall thickness needs to be greater than 5mm before automatic filling and capping work. This equipment adopts the pipe fixing, and the equipment is adsorbed on the pipe or the customized track through the permanent magnet wheel for automatic welding. The welding efficiency is high, the forming is stable, and the welding quality is guaranteed. During welding, the welding head crawls on the pipe, and the pipe does not need to be rotated or moved, and the welding head can realize automatic welding. During the welding process, the operator can fine-tune the welding process of the equipment through the wireless remote control, so as to ensure the welding quality.

Pipeline automatic welding machine function: it can be used for filling welding and cover welding in the pipeline welding process, also suitable for horizontal horizontal welding and vertical welding of tank body, and can also be used for flat plate welding, suitable for two welding processes of GMAW/FCAW-GS;

The configuration of different tracks is also suitable for all-position welding requirements of other workpieces.

Pipeline automatic welding machine configuration: welding trolley (with integrated wire feeding mechanism), wireless remote control, digital welding power source (including pulse function, more accurate and stable welding)

Pipeline automatic welding machine features:

High-definition wireless handheld LCD remote control operation, can directly preset parameters, etc.;

Automatic welding and manual welding can be freely selected, and the swing angle and swing function can be freely switched. The system uses the remote control to call the corresponding parameters to achieve smooth transition of welding parameters of each layer and accurate all-position welding;

The equipment is easy to operate, easy to learn, and comprehensively reduces the labor intensity of welders;

It can realize all-position welding of 1G, 2G, 3G, 4G, 5G, etc.;